Construction & Industrial Workwear Manufacturer

- Share

Specializing in custom construction and industrial clothing | Uniouter

At Uniouter, we don’t simply sell construction and industrial clothing.

We manufacture workwear solutions that are truly designed for real industrial job sites, built to perform in harsh working environments and withstand long-term use.

With over 20 years of experience in functional apparel manufacturing, we help brands, contractors,distributors, and project procurement teams significantly reduce risks related to quality consistency,cost control, and long-term supply reliability.

Uniouter construction and industrial workwear, customized exclusively for brands and trading companies.

Nowadays, workwear not only needs to look professional with a clean, precise fit, but it must also withstand real industrial conditions in terms of durability, protection, comfort, and functionality.

Uniouter is dedicated to combining industrial-grade functional fabrics, scientific structural design, and a stable manufacturing system to create workwear solutions for construction, manufacturing, and heavy industry clients that are both practical and durable, while reinforcing brand identity—helping your brand and distribution channels maintain a long-term competitive advantage in a demanding market.

Request a quotation

| COMMON PAIN POINTS WE ELIMINATE: | UNIOUTER | YOUR BENEFIT |

|---|---|---|

| Lack of compliance documentation for EU EN and US ANSI standards. | Compliant with EU and US regulatory requirements, verified through rigorous testing. | All fabrics come with test reports and support third-party re-inspection. |

| Poor quality control leading to discrepancies between samples and final goods, including color mismatches, shrinkage, and stitching defects. | Rapid Sampling: Samples Delivered in 7–14 Days with Complimentary Sample Policy. |

Samples Precisely Mirror Bulk Production Processes, Ensuring Quality Assurance. |

| High MOQs (Minimum Order Quantities) often start at 1,000 units, making it difficult to test new markets or cater to niche job requirements. |

Low MOQ: Starting from only 300 pieces, with flexible multi-style bundling options. |

Breaking Down the High MOQ Barriers of Traditional Workwear to Empower Your Rapid Market Testing. |

| Outdated styles and fabric technologies that fail to align with current market trends. | A professional design team dedicated to staying ahead of the latest industry trends. | Tailored solutions designed specifically for your unique needs. |

| Lack of brand consistency across different product lines. |

Comprehensive end-to-end manufacturing capabilities. | Complete Category Coverage: Including Jackets, Outerwear, and Trousers. |

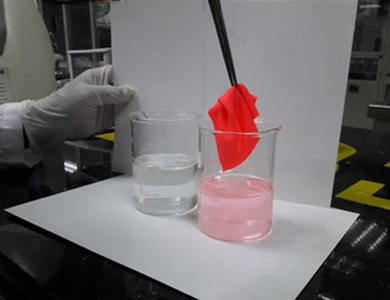

Professional Experiments in Fabrics and Technology

Uniouter conducts in-depth analysis on core technologies such as FR coatings, DWR coatings, and seam tapes. We possess leading fabric performance and craftsmanship.

We use scientific experiments to verify every inch of fabric, ensuring genuine and reliable performance.

International Certification and Compliance Standards

Uniouter has obtained multiple comprehensive certifications including EN ISO 11612 and NFPA 2112, and is very familiar with the compliance standards of markets such as the European Union and North America.

Every product meets international environmental protection and safety standards.

20 Years of Manufacturing Experience and Success Stories

Founder Cathy Wang has over 20 years of experience in the workwear industry and has led many high-difficulty customization projects.

Case: Customized workwear for Estonian government departments to cope with extreme working environments, receiving high praise.

Transparent Quality Inspection Process

A three-stage quality inspection system covers three phases: fabrics, in-production, and finished products, ensuring every item meets the standards.

Customer reviews and abstracts of third-party test reports are made public, enabling full traceability and building long-term trust.

Most merchants struggle to find a perfect match between the factory samples and their creative vision. Leveraging advanced manufacturing capabilities and an experienced team, Uniouter bridges this gap, ensuring your designs are perfectly replicated. We strive for perfection in every detail—from logo placement and fabric hand feel to pattern cutting.

Utilizing our OEM/ODM solutions, you can customize every aspect of your activewear—from fabrics and logos to stitching and silhouettes. Uniouter offers high-precision logo printing, high-performance fabrics, and style upgrade services, helping your products stand out in a competitive market.

How to forge collaborative relationships with construction and industrial apparel manufacturers

-

1

Step 1: Determine the type of construction and industrial garments you want to produce (e.g., jackets, t-shirts, work pants), your target customers, design style, and quality level.

-

2

Step 2: Submit your technical package or reference images and request custom samples to check the accuracy of fabric, fit, sewing craftsmanship, and logos.

-

3

Step 3: Discuss minimum order quantities, delivery times, and customization options, confirming sample and bulk production timelines (e.g., 7-14 days for samples, 30–50 days for bulk production).

-

4

Step 4: Ensure smooth communication, project tracking, quality control, and after-sales support are in place. Uniouter provides quick response, dedicated account managers, and systematic real-time updates.

-

5

Step 5: Start with a small order to test collaboration efficiency, product consistency, and shipping reliability before scaling up.